Components of polymeric systems

Polymeric systems according to EN 12068 and ISO 21809-3

List of kebu polymeric systems

Class C-50°C:

KEBULEN B-80 C tape (4 layers) * *

System KEBUTYL B-80 C / B-50 B * *

KEBUTYL C50 system (KEBULEN 1.2 H + KEBULEN PE 0.50) * *

* with KEBUTYL K III primer * DVGW approved

Implementation

PROTECTION OF A PIPE BY KEBUTYL SYSTEM

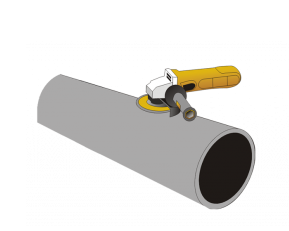

Surface preparation

The surface can be cleaned by mechanical or manual brushing.

Care should be taken to remove dust and other dirt, rust not

adherent and generally any particles likely to be found

between the metal surface and the coating tape. The surface should be

dried; if necessary, use a propane burner.

We recommend prior preparation to achieve a

condition corresponding to level SA 2.5 of standard EN ISO 12944-4.

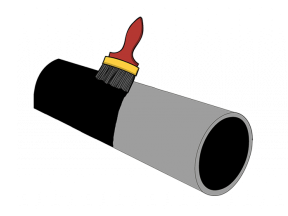

Step 1: application of the primer

The primer is essential before applying the polymer tapes*.

Follow the implementation instructions and respect the drying time

*except OP bands

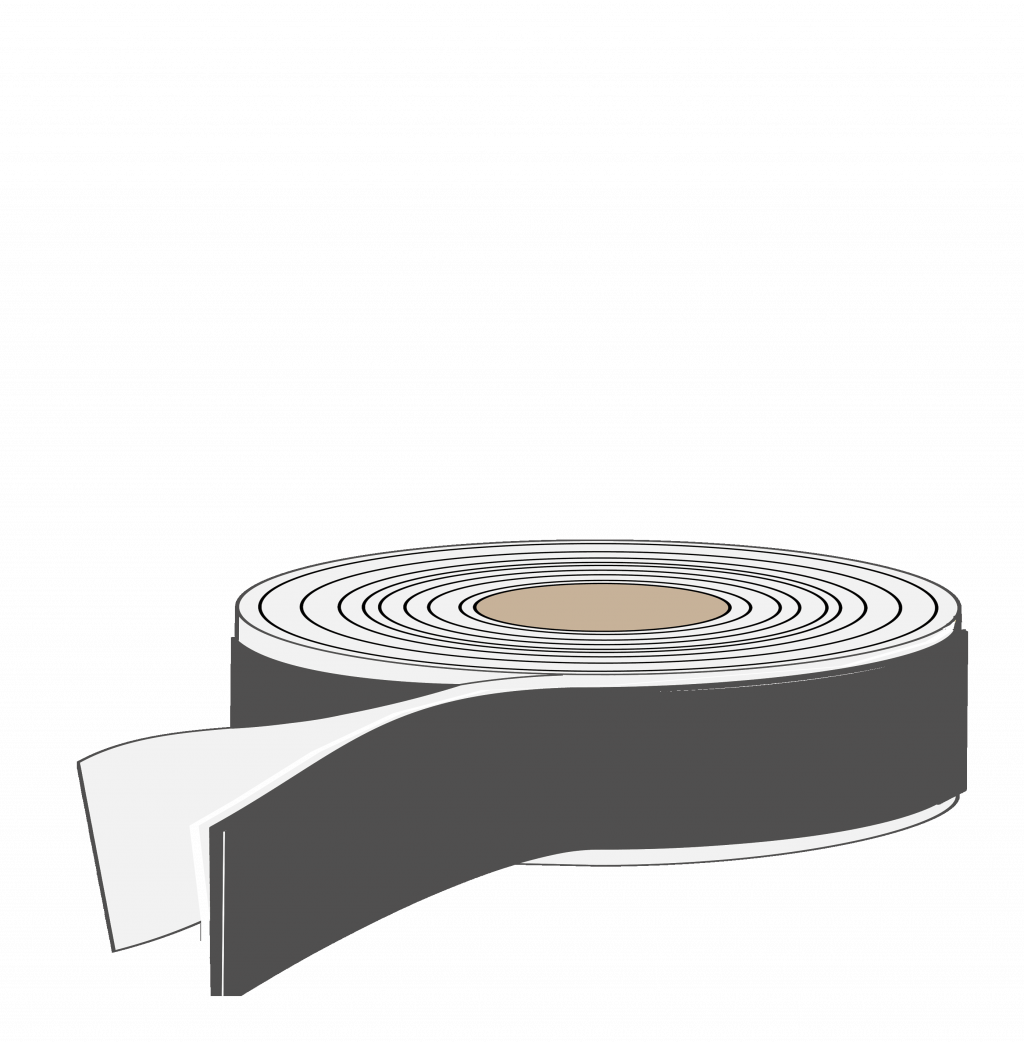

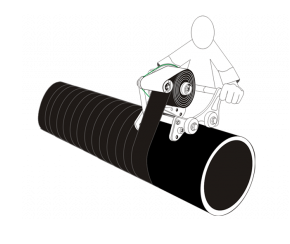

Etape 2: application of the KEBULEN anticorrosion tape

In order to meet the requirements of the EN 12068 and ISO 21809-3 standards, the

anti-corrosion tape must in particular merge on itself, to avoid

infiltrations at the overlaps of the wraps. As a result, the

corrosion protection tape is always fitted with a release liner, which must be removed

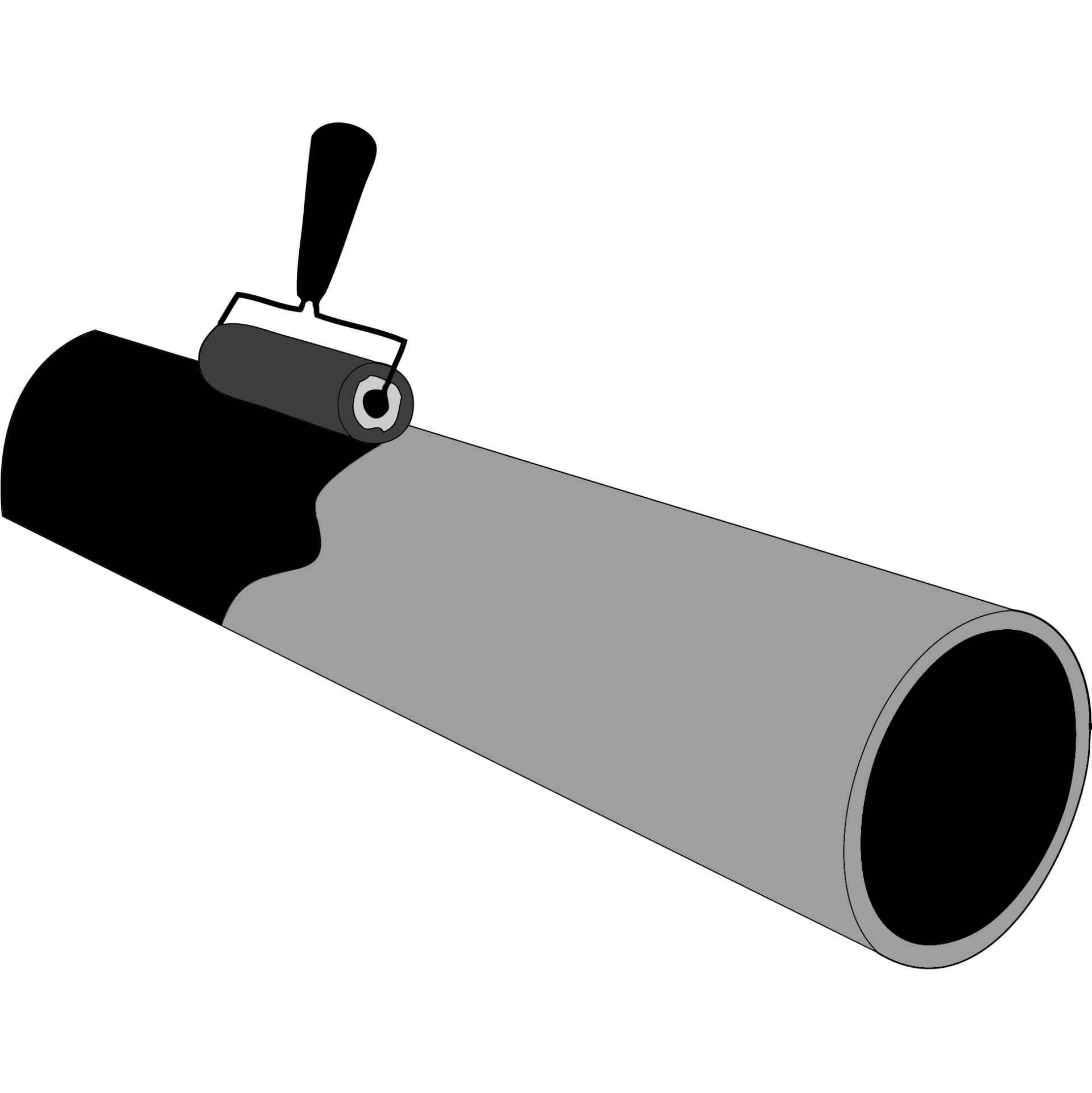

as the coating progresses. The use of a KEBUMAT coating machine ensures easy application with a regular tension and covering. The KEBUMAT machine is equipped with an release liner recuperator.

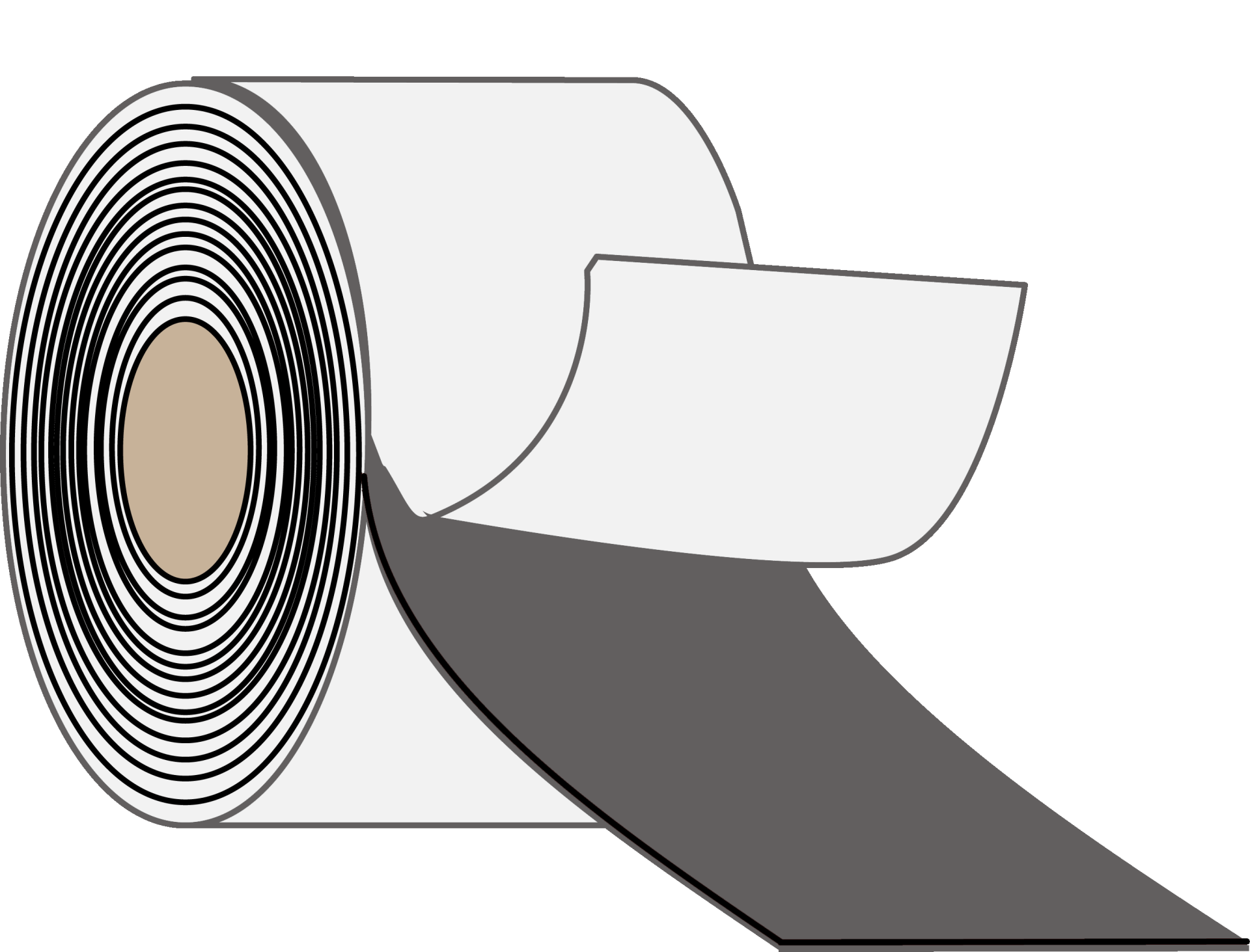

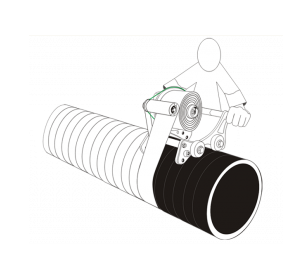

Step 3: application of the KEBULEN mechanical protection tape

The mechanical protection tape amalgamates with the adhesive outer layer of the anti-corrosion tape. The start of the coating should be made slightly out of step with the first tape.

This is not an exhaustive user manual - contact us for implementation details.