Anti-corrosion coatings for pipelines

Cold applications

Petrolatum systems

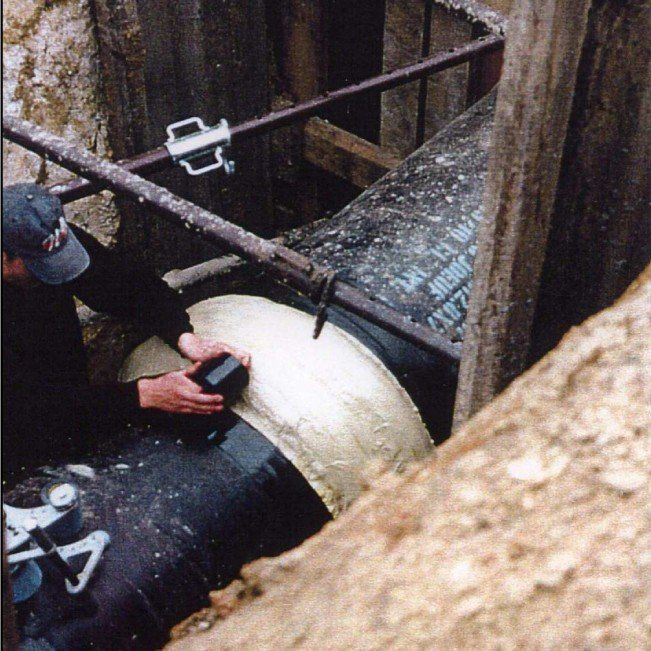

Petrolatum systems are characterized by the absence of a primer and great ease of implementation. They are applied after brushing, on surfaces even wet for some and at low temperatures. Flexible, not requiring high tension during application, they can be applied manually without difficulty, even in places that are difficult to access.

Polymer systems

Polymer systems work by adhesion to the steel surface and therefore require the prior application of a primer. They require careful surface preparation (SA 2.5) and must be applied at positive temperatures on dry surfaces (surface temperature above the dew point). They are applied under tension, preferably by machine. Their high mechanical resistance makes them particularly suitable for large diameter pipes in aggressive environments.

Visco-elastic systems

Visco-elastic systems combine the advantages of traditional tape systems: surface preparation by simple brushing, no application of primer and excellent immediate adhesion to the substrate.

Hot applications

Heat shrinkable

Heat-shrink systems are based on a cross-linked polyethylene that contracts under the effect of heat, allowing them to adopt the shape of the structure to be protected. Under the effect of heating, the adhesive with which the support is coated softens and the retraction presses it against the support. Depending on the type of adhesive, the prior application of a primer may be necessary. Heat-shrink sleeves offer high mechanical resistance and are used for the protection of weld joints mainly, after sandblasting or shot blasting of the surface.

Renovation of old coatings

Repair and replacement of defective coatings

Depending on the composition and condition of the old coating, as well as the intervention conditions, we offer several systems to give new life to your installations.

Approved systems

List of approved kebu systems according to EN 12068

Class A-30°C: KEBU Band A-303 *

Class B-30°C: KEBU BITUMENBAND GW tape (Hot applicable) *

KEBU BITUMENBAND Spezial Tape (Hot applicable) * *

KEBUTYL B30 system (TESTO 1.5 strip KEBULEN PE 0.25 or 0.40) ** *

Class C-30°C: KEBUTYL C30 system (TESTO 1.5 H strip KEBULEN PE 0.25 or 0.40) ** *

Thermoretractable KEBULEN SM C30

Class B-50°C: KEBULEN B-80 C strip (3 layers) ** *

Class C-50°C: KEBULEN B-80 C strip (4 layers) ** *

KEBUTYL B-80 C / B-50 B system (2 x 2 layers) ** *

KEBUTYL C-50 C System (1.2 H TEST band 0.50 KEBUTYL band) **

Thermoretractable KEBULEN SM C50 *

* with KEBUSOL KIII primer * approved by SYNERGRID

* with KEBUTYL KIII primer

GRTGaz and GRDF AUTHORIZED EMPLOYMENT SYSTEM

PBM01 BUILDING

AIR LIQUIDE APPROVED SYSTEM

TEDO P-PASTE Anti-corrosion tape A303 or green tape

KEBU PE 0.50 TEDO PFM mastic